Typically, within the beer brewing process, 2.5 liters to 3 liters of water are used per liter of beer produced. As Mexico is one of the leading beer producers and the top exporter worldwide, surpassing even countries with a brewing tradition, the adoption of new technologies is of great importance. These technologies help improve process efficiency and reduce or eliminate product waste when conducting necessary quality control tests to ensure consumer safety.

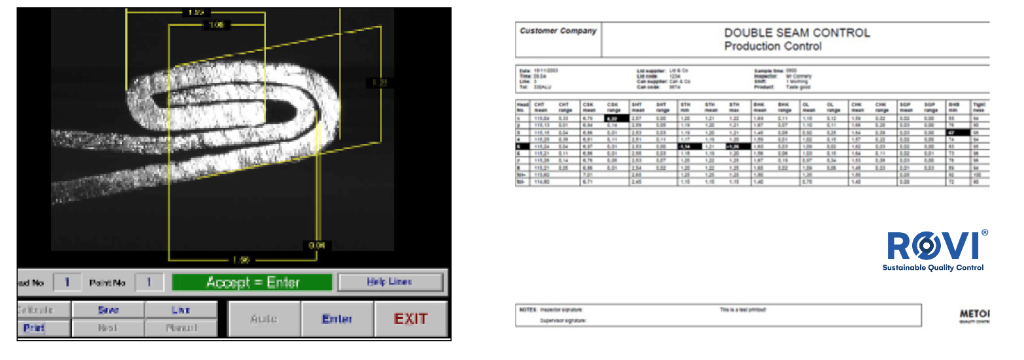

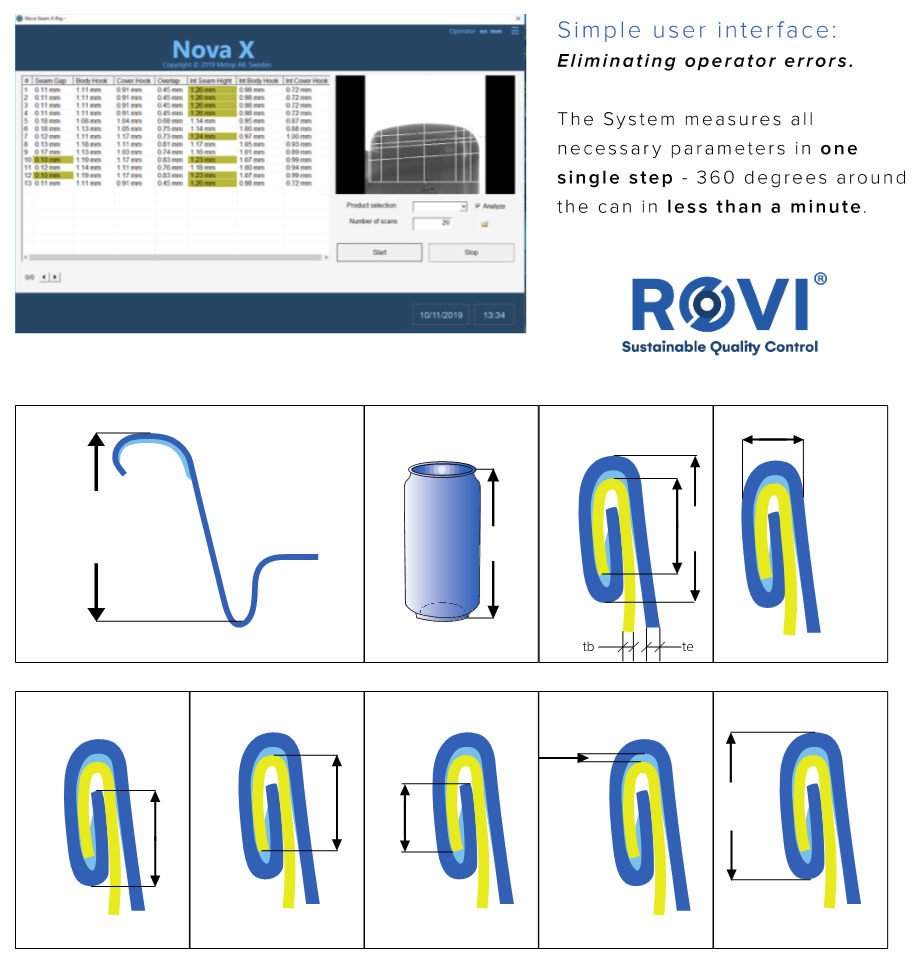

In canning lines, after the filler, quality tests on the double seal are performed by cutting the sample, requiring the disposal of the product. Subsequently, a comparison is made with a special camera to assess established parameters in the packaging (distances) to determine if it has been sealed with the necessary hermeticity. This process aims to prevent internal gas leaks and product contamination (Figure 1).

Taking as an example one of the industrial breweries considered small in Mexico, which has a single canning line (5 million hectoliters annually), 5,040 “five thousand forty” destructive tests are conducted on finished products (335ml cans) each month. This results in a monthly loss of 1,690 liters of beer, equivalent to 5,065 liters of water.

The use of a system that helps us perform non-destructive tests on the packaging of our beverages is crucial when it comes to saving both the product and, more importantly, water.

This technology is available through X-rays, and with these images, a distance comparison is made in the same way as the mentioned traditional method but with greater accuracy. It also reduces the testing time and the human error factor (Figure 2).

Additionally, in these samples, 5,040 aluminum cans are wasted, which will need to be recycled, involving energy expenditure.

The potential impact for water and product savings becomes very high considering that in the manufacturing of beer, soft drinks, juices, and other beverages, this type of quality inspection is carried out.

Can you apply these benefits in your area of responsibility?

For more information, please contact us at: +1 847 363 0191 / +1 847 363 0177